Audemars Piguet has long established itself as one of the oldest manufactures still in the hands of the founding families. Embodying the Swiss tradition of watchmaking, the Manufacture has established itself as a timeless, forward-thinking brand.

For over a century, Audemars Piguet has been at the forefront of watch mechanism and design, having created many records such as the world’s first automatic tourbillon wristwatch in 1986, which contained the smallest tourbillon cage and the first to be made from titanium. It also introduced the world’s first self-winding perpetual calendar wristwatch in 1978 and more recently in 2019 it produced the world’s thinnest self-winding perpetual calendar wristwatch.

The combination of artistic excellence and design mastery also endows the Swiss Haute Horologerie manufacturer’s latest collection Code 11.59 by Audemars Piguet.

Launched at the beginning of 2019, Code 11.59 by Audemars Piguet brings advanced technology together with time-honoured traditional methods to create a unique piece of beauty and technical intricacy.

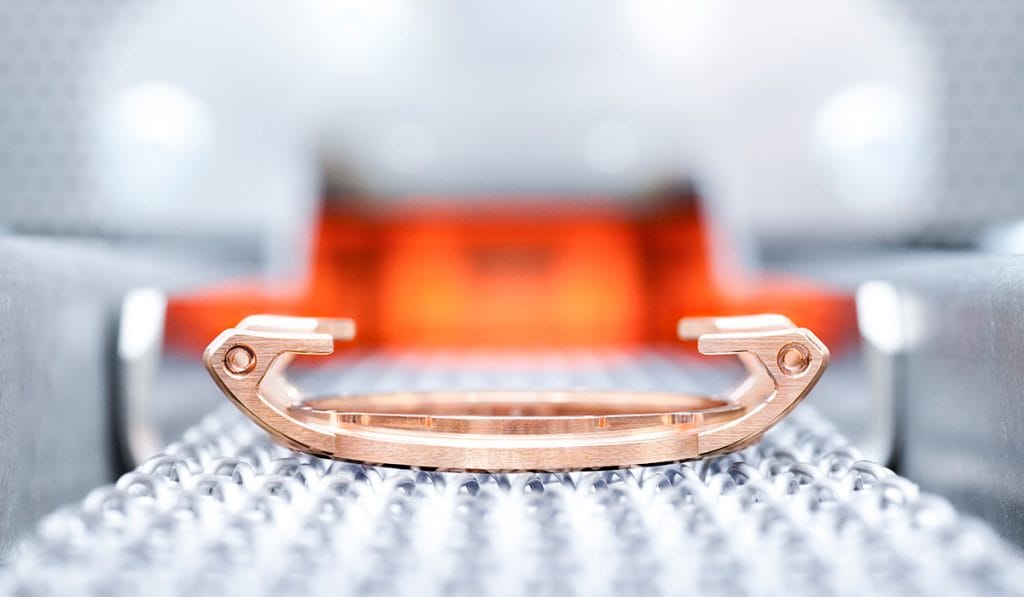

The case of the Code 11.59 by Audemars Piguet is endowed with a contemporary architecture that unites an octagonal middle case with a round extra thin bezel and stylised arched lugs.

To create the case’s multiple geometries and ergonomic curvature, Audemars Piguet had to utilise complex programming, dedicated tools and highly specialised human talents.

For the ï¬nishing touch, each piece is carefully brushed by hand.

Take a closer look and you will see that the glass’ internal surface is shaped like a dome with its external surface vertically curved from 6 to 12 o’clock. This play with depth, perspective and light provides a unique visual experience that must be seen in person to be truly appreciated.

Openworked lugs complement the case’s multifaceted architecture. These upper lugs were welded to the extra-thin bezel while the bottom lugs lean delicately against the caseback in perfect alignment.

New processes challenging traditional production standards were developed in order to achieve this with each lug individually soldered to the bezel with a soldering paste applied by hand. To hide the soldering paste, an expert polisher delicately polishes the welded junctions of the lugs, rendering it invisible once the watch is fully assembled.

Keeping with the Manufacture’s traditions, each Code 11.59 by Audemars Piguet timepieces has been meticulously polished and satin-brushed by hand. The case’s angular and rounded surfaces provide a real challenge to the finishing experts, requiring a highly specialised team comprised of 6 polishers and 5 satin brushing specialists.

This interweaving of polishing and satin brushing, popularised by the Royal Oak in 1972, has adorned many of the Manufactuer’s wristwatches throughout the 20th century. From its conception to the final touch, the case of the Code 11.59 by Audemars Piguet offers myriads of contrasting details that give life to this multifaceted piece.